Najważniejsze informacje dla klientów

Nasi klienci są kluczem do naszego sukcesu!

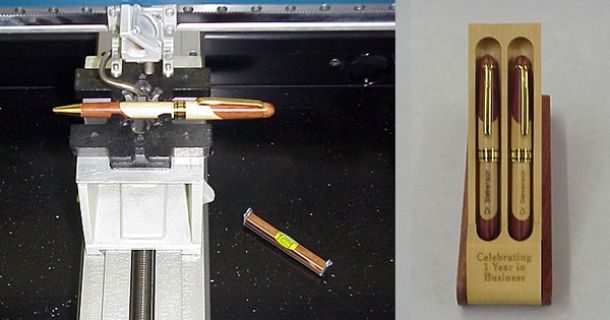

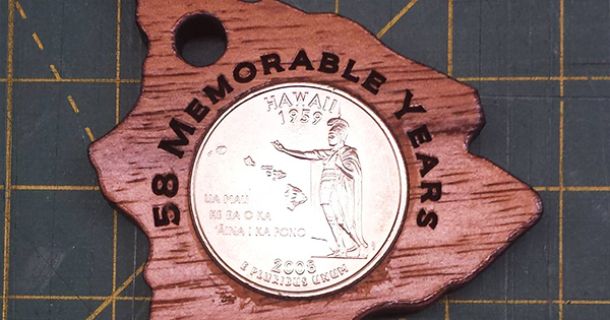

Nasi lojalni i innowacyjni klienci stanowią dużą część sukcesu firmy Epilog Laser. Ciągle dowiadujemy się o klientach, którzy wykorzystują nasze systemy laserowe w wyjątkowy i kreatywny sposób. Poniżej znajdą Państwo szereg informacji o klientach i historie sukcesu, które szczegółowo opisują, w jaki sposób niektórzy z naszych klientów wykorzystują swoje systemy laserowe i jak tworzą i utrzymują swoje dobrze prosperujące firmy. Uwielbiamy słuchać o tym, jak nasi klienci korzystają z systemów laserowych Epilog.

Czy uważa Pan, że może ma Pan własną historię, którą chciałby się podzielić?